Forum #XMOTIVE

Produce Future Mobility

Electromobility, fuel cells, Power2X - The change in mobility is multi-layered and in the future there will not be just one type of drive on the market. This poses new challenges for the entire industry.

The transformation process must be actively supported. In order to meet the current challenges, the VDMA supports its members.

Shutterstock

exklusiv

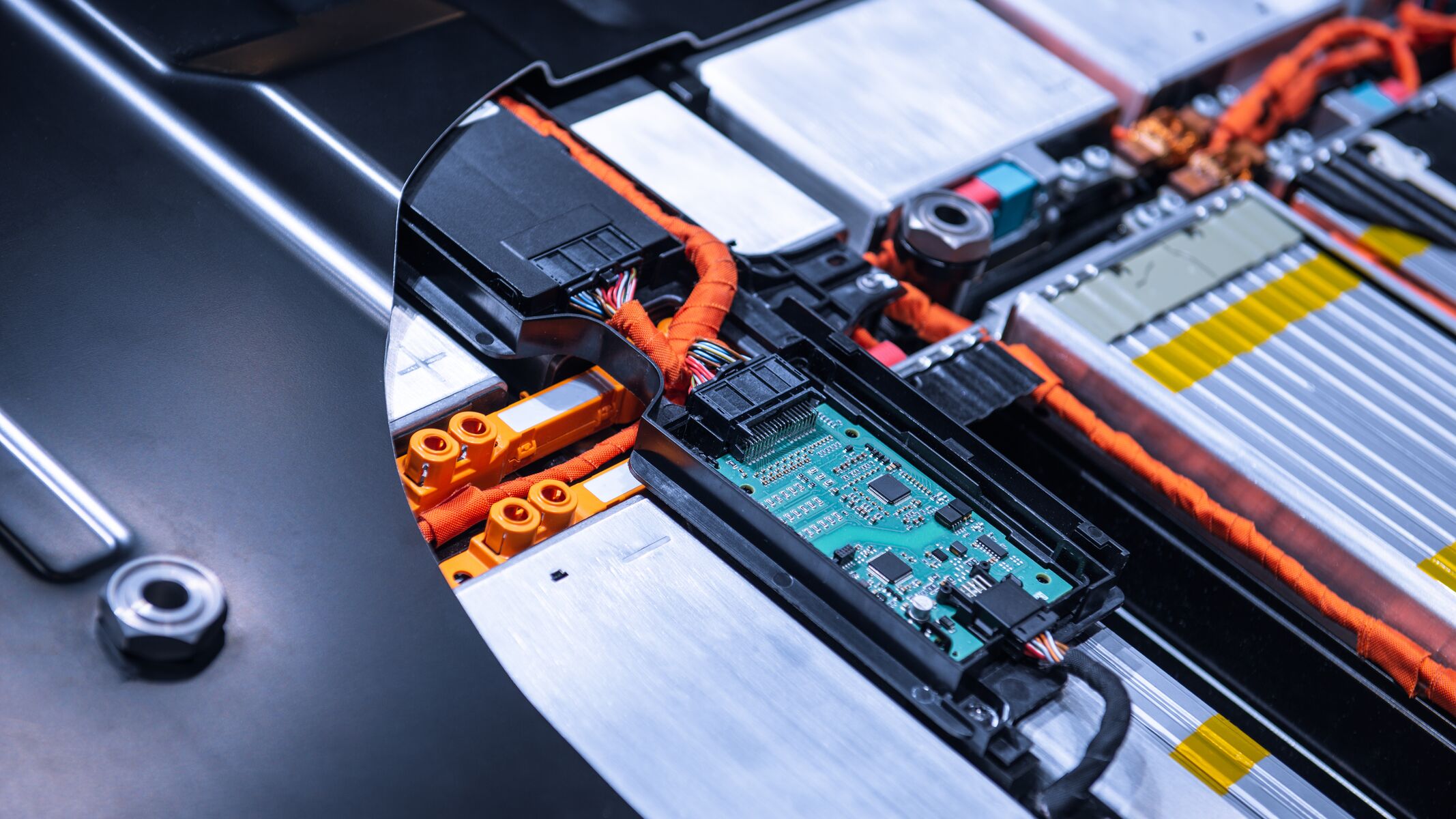

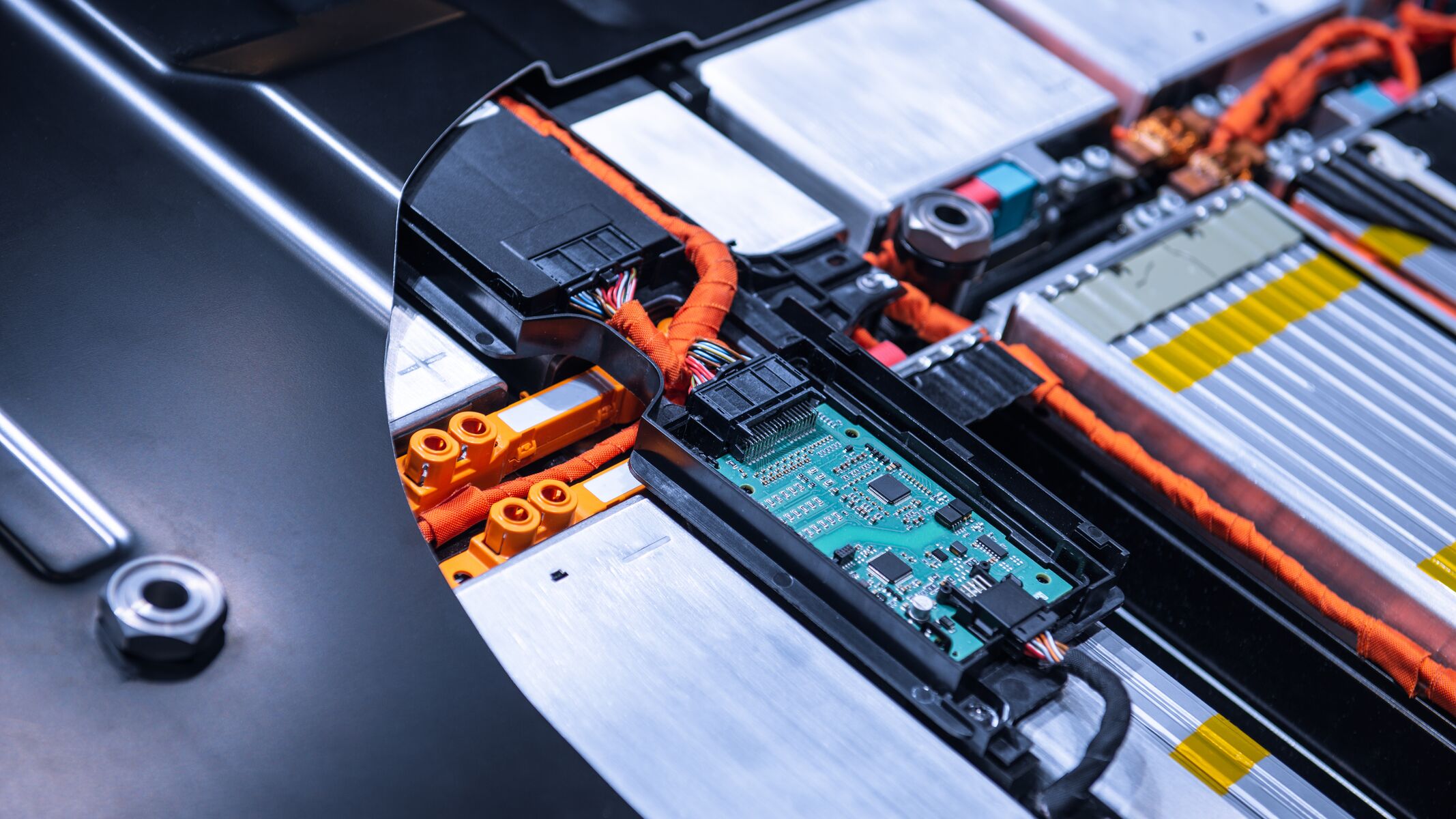

Standardized interfaces and flexible production concepts are essential for battery production and Industry 4.0. The VDMA and VDA are promoting this through a Joint Working Group.

Regarding intelligent, sustainable battery production, it is important to understand the interaction of complex production lines, reduce costs and ensure process stability.

Are you looking for strong solutions not only for large-scale production for battery manufacturing? Access the expertise of our mechanical and plant engineering manufacurers. In addition to the thematic search function, the new online format offers the possibility to contact the battery experts of the respective companies.

Challenges of mechanical engineering: While Asian mechanical engineering is establishing itself in battery production in Europe, the domestic industry is threatening to fall behind.

Sales growth of over 17 percent is expected for the current year, and around 25 percent for 2022. The European market is taking an increasingly strong position in this regard.

VDMA Battery Production and Fraunhofer Research Production Battery Cell Münster to jointly develop production solutions

VDMA publishes brochure on battery recycling

By 2040, around 45 percent of vehicles worldwide will be powered purely by electricity or fuel cells. For the mechanical engineering industry, this means opportunities and challenges, which are examined in the third edition of the study "Drivetrain in Transition".

The third edition of the study series deals with the electrification of the powertrain and its impact on the industry.

Mobility is becoming more diverse. The change in mobility is set. Hybridization and electrification are increasingly becoming the standard. Mechanical engineering is the focus here - it produces mobility.

The energy turnaround will not work without the expansion of renewable energies. In addition, high-density energy sources are needed. Mechanical and plant engineering plays a leading role in both areas. Here, China is an exciting export market.

Study on the battery production market and process engineering challenges essential for the industrial production of Li-ion batteries for electromobility and stationary storage.

Despite the pandemic, battery machine manufacturing remains a growth market of strategic importance. Europe as a location is gaining momentum in a global comparison.

The E-MOTIVE forum is intensively involved in research activities for the further development of electric mobility.

Electric mobility, fuel cell, power-to-x - the change in mobility is complex and in the future there will not be just one type of drive on the market.

Hyper-high speed for the electrified automotive powertrain to achieve maximum ranges In the Speed4E project, experts from industry and science are working together to develop an innovative hyper-high-speed drivetrain for use in electrified automobiles.

European mechanical and plant engineering industry as an attractive partner for battery manufacturing

Monday, March 16th, 2020, 1:00 p.m. - 8:00 p.m.at Renaissance Brussels Hotel, Rue du Parnasse 19, 1050 Bruxelles, Belgium

The current business climate survey by VDMA Battery Production shows the growth expectations of machine and plant manufacturers in battery production. Sales growth of 4 percent is expected for the current year. By 2020, the figure should even be 9 percent - and this in an environment of global economic weakness and trade disputes.

The diversity of requirements in the respective markets also requires a diversity of available technologies. Tomorrow's mobility will be achieved through mechanical engineering - and requires openness to new technologies.

For the production of Li-ion batteries, the process steps for the production of Li-ion cells, module/packs, components, all-solid-state cell and battery recycling are presented clearly and in detail.

After the Roadshow is before the Roadshow: After the successful event 2017 in Korea at Samsung SDI and LG Chem and this year's Roadshow 2018 in China at CATL, ATL, BYD and BAK, preparations are underway for our next Roadshow 2019 in the USA. Please be there!

Following the 2017 roadshow in Korea at Samsung SDI and LG Chem, a delegation of 27 mechanical and plant engineering companies will travel to China in May 2018 to present their expertise along the process chain of Li-ion battery production on site.

Topic in Focus

Veranstaltungen & Messen

Your contact